Aluminum Foundry Basics: What You Need to Know

Grasping the basics of aluminum foundry operations is vital for everybody working in manufacturing. This encompasses understanding the nuances of the casting process, recognizing the diverse mold types, and complying with safety protocols. Each aspect plays a vital role in maintaining quality and efficiency. As industries progressively rely on aluminum castings, familiarizing oneself with these basics can result in significant advantages. What specific elements make up the aluminum casting process?

Aluminum Casting: A Step-by-Step Process

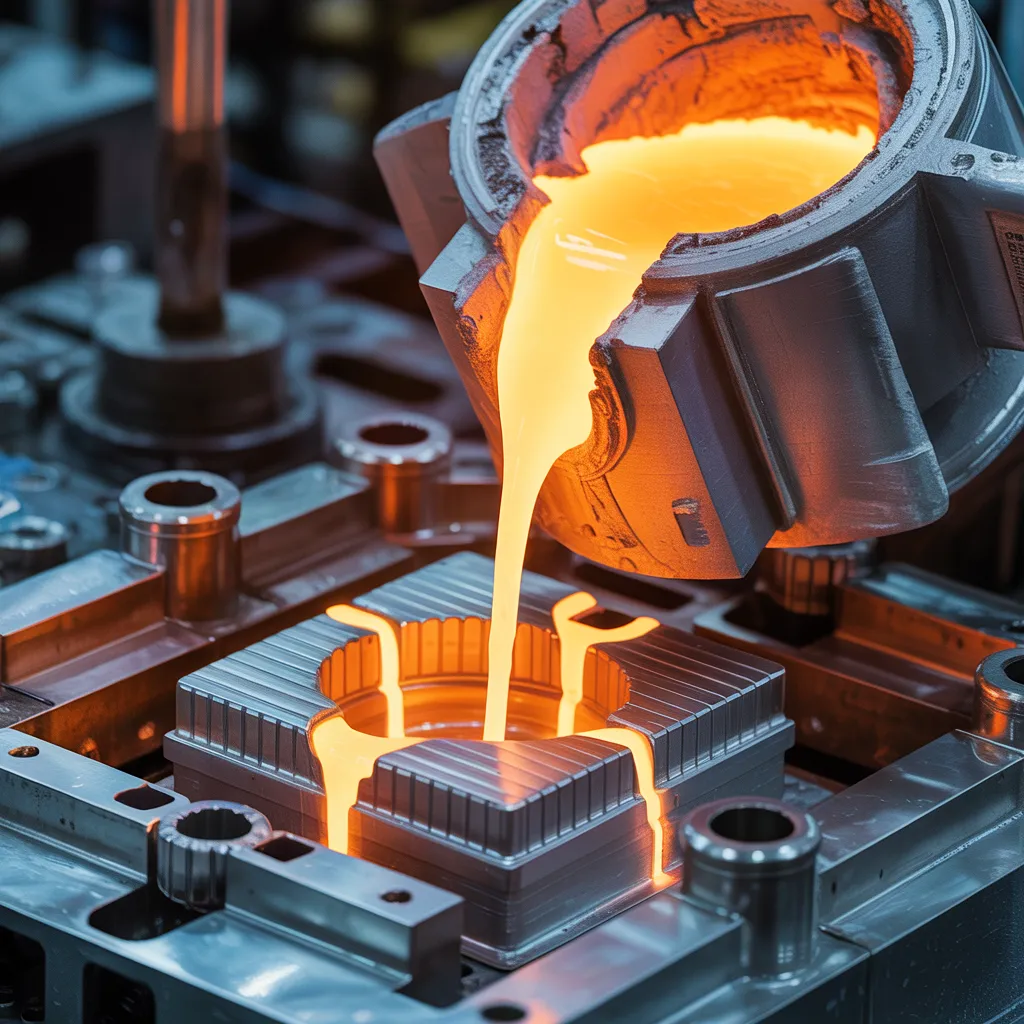

The aluminum casting procedure generally includes various important steps that convert raw aluminum into finished products. Initially, the process begins with melting the aluminum, which is commonly carried out in a furnace. The liquefied aluminum is then dispensed into molds created to form the final product. These molds can be fabricated from various materials, including sand or metal, based on the production requirements.

After the aluminum has cooled and become solid within the mold, the next step is to extract the casting. This is frequently achieved by demolishing the mold or employing mechanical means. Upon removal, the casting experiences various finishing processes, which may involve trimming surplus material, grinding, and polishing to achieve the desired surface quality.

Lastly, quality control inspections are performed to ensure the components fulfill specified standards. This step is vital in assuring that the final products are appropriate for their intended applications in various industries.

Attributes of Aluminum

Aluminum exhibits a distinctive combination of properties that make it a highly sought-after material in various industries. Its lightweight property, with a density approximately one-third that of steel, provides ease of handling and supports fuel efficiency in transportation applications. Furthermore, aluminum displays outstanding corrosion resistance resulting from the formation of a protective oxide layer, prolonging its lifespan in different environments.

This material is also recognized for its outstanding strength-to-weight ratio, allowing for the creation of additional article strong yet lightweight structures. In addition, aluminum is very malleable and ductile, which makes it appropriate for diverse manufacturing processes, including casting, extrusion, and machining.

Other notable characteristics include thermal and electrical conductivity, facilitating its use in heat exchange systems and electrical parts. Furthermore, aluminum is 100% recyclable without quality loss, supporting sustainable practices and minimizing environmental impact in sectors that employ it.

Types of Molds in Aluminum Foundries

Different mold types are used in aluminum foundries to accomplish various casting methods and meet product specifications. Sand molds represent the most common type, permitting intricate patterns and are generally utilized for one-time or limited production runs. Permanent molds, typically made of metal, are used for high-volume production and provide better dimensional accuracy and surface finish. Investment casting molds, created using a wax pattern coated in ceramic, are ideal for complex shapes with fine details. Additionally, shell molds, which consist of a thin shell of sand and resin, offer excellent surface finish and are suitable for medium production runs. Each mold type has its unique advantages and is selected based on factors such as production volume, complexity of the part, and desired finish. Understanding these mold options is vital for achieving best results in aluminum casting processes.

Critical Equipment for Aluminum Casting Excellence

Productive aluminum foundries require specific equipment to provide efficient operations. Key components include melting furnaces for material processing, molds and patterns for shaping, and essential safety gear to protect workers. Comprehending and investing in these must-have items is essential for achieving ideal results in aluminum casting.

Essential Melting Furnace Components

Upon establishing a successful aluminum foundry, picking the right melting furnace is crucial, as it directly determines the quality of the final product. Important factors include furnace type, capacity, and energy efficiency. Standard types of melting furnaces include crucible, induction, and reverberatory, each delivering distinct advantages for different production scales. The furnace capacity must align with the foundry's production demands to assure timely processing. In addition, energy efficiency is critical for decreasing operational costs. Appropriate temperature control is critical for attaining consistent melt quality and preventing contamination. Acquiring reliable refractory materials increases furnace durability and thermal efficiency. In the end, the right melting furnace brings significantly to the foundry's overall performance and product integrity.

Pattern and Mold Systems

Molds and patterns act as the backbone of aluminum foundry operations, directly influencing the precision and quality of castings. These tools are vital for shaping the desired shapes and dimensions of the final product. Patterns, usually made from metal, wood, or plastic, are used to form molds that hold the molten aluminum until it solidifies. The decision of material influences the mold's durability and heat resistance. Furthermore, the design of molds must consider factors like shrinkage and ease of removal, providing high-quality outputs. Foundries commonly utilize different mold types, such as sand molds and permanent molds, depending on production requirements. Understanding the intricacies of molds and patterns is essential for achieving optimal casting results in aluminum foundry operations.

Safety Equipment Requirements

Within aluminum foundry settings, safety equipment standards are critically important to protect workers from the potential hazards related to molten metal and heavy machinery. Vital safety equipment includes heat-resistant gloves to stop thermal injuries, safety goggles to guard eyes from flying debris, and face shields to defend against splashes of molten metal. Workers need to wear fire-resistant garments and steel-toed boots to protect from heavy objects and heat exposure. Moreover, ear protection is essential due to the excessive sound levels created by machinery. Proper respiratory gear may be required to stop the inhalation of harmful fumes. Following these safety gear requirements not only ensures worker safety but also promotes a more efficient and productive foundry operation.

Safety Procedures in Aluminum Casting

When it comes to aluminum casting, implementing safety practices is vital to safeguard workers from potential hazards. Important factors consist of implementing personal protective equipment, guaranteeing sufficient ventilation, and creating emergency response procedures. Such precautions combine to foster a safer operational setting in the foundry.

PPE - Personal Protective Equipment

A complete grasp of personal protective equipment (PPE) is essential for guaranteeing safety in aluminum casting operations. Appropriate PPE includes gloves resistant to heat, face shields, and safety goggles to defend against molten metal splashes and heat exposure. Workers should also wear fire-retardant attire and steel-toed boots to minimize injury risks from heavy equipment and hot materials. Respirators may be essential to shield from harmful dust and fumes generated during the casting process. Additionally, hearing protection is advisable due to high noise levels in foundry environments. Regular inspection and maintenance of PPE are vital to confirm effectiveness. By adhering to these safety practices, workers can substantially reduce the risk of accidents and injuries, encouraging a safer workplace for all involved in aluminum casting.

Airflow Specifications

Effective ventilation is a critical component in guaranteeing safety within aluminum casting operations. Appropriate airflow decreases the collection of hazardous fumes and dust produced during the melting and pouring processes. It is crucial to design ventilation systems that successfully exchange indoor air with fresh outdoor air, preserving safe breathable conditions. Local exhaust ventilation systems should be placed near sources of pollutants to capture them at the source. Furthermore, air monitoring systems can help measure air quality, safeguarding compliance with occupational health standards. Regular maintenance and inspection of ventilation equipment are essential to guarantee maximum performance. By focusing on proper ventilation, foundries can notably reduce the risks linked with air contaminants, promoting a safer working environment for all employees involved in aluminum casting.

Emergency Management Procedures

Being prepared is vital in aluminum casting operations, where the potential for accidents necessitates well-defined emergency response procedures. Developing a clear plan is critical for protecting employees and minimizing damage. Key elements of these procedures include identifying emergency exits, ensuring accessible first aid kits, and conducting regular safety drills. Employees must be trained to identify potential hazards, such as molten metal spills and equipment malfunctions, and know how to react appropriately. Communication protocols should be established, allowing for prompt reporting of incidents. In addition, designated personnel should be assigned to lead emergency responses, facilitating a coordinated effort. Regular reviews and updates of these procedures are essential to adapt to any changes in operations or equipment. Safety is everyone's responsibility in the foundry environment.

Well-Known Industries Employing Aluminum Castings

Aluminum castings play an essential role across various industries, displaying their flexibility and robustness. The automotive field is one of the largest consumers of aluminum castings, using them for engine housings, transmission housings, and wheels. Their lightweight properties leads to better fuel consumption and performance. The aerospace industry also profits from aluminum castings, where components are manufactured to endure extreme conditions while limiting weight. Additionally, the electronics sector employs aluminum castings for casings and heat sinks, guaranteeing optimal thermal management in devices. In construction, aluminum castings are used in window frames, railings, and support structures, offering longevity and resistance to corrosion. Additionally, the consumer goods industry employs aluminum castings for various products, from cookware to furniture, showcasing their visual attractiveness and functional properties. All in all, the versatility of aluminum castings makes them indispensable in various sectors, enhancing product performance and longevity.

Questions & Answers

What Are the Environmental Effects of Aluminum Foundries?

Aluminum foundries result in environmental impacts through waste generation, energy consumption, and greenhouse gas emissions. Additionally, they can release particulate matter and other pollutants, possibly impacting air quality and surrounding ecosystems if not appropriately regulated.

What Steps Are Needed to Start My Own Aluminum Foundry?

To launch an aluminum foundry, one must carry out market research, obtain financing, get essential permits, pick suitable machinery, and develop a skilled workforce, ensuring compliance with environmental regulations and safety standards within the process.

What Are Frequent Defects in Aluminum Castings?

Typical defects in aluminum castings include porosity, shrinkage defects, incomplete fills, cold shuts, and surface irregularities. These problems commonly result from inadequate melting temperatures, insufficient mold design, or poor metal flow, influencing the final casting's quality and strength.

How Do Foundries Integrate Aluminum Recycling?

Aluminum recycling becomes part of foundry operations through the collection and processing of aluminum scrap, which undergoes melting and reuse in production. This approach decreases material expenses, saves energy, and lessens environmental impact, advancing sustainability in manufacturing.

What Certifications Are Required for Aluminum Foundry Operators?

Those working in aluminum foundries generally require certifications in safety protocols, metallurgy, and equipment operation. Certifications recognized by the industry, such as those provided by the American Foundry Society, ensure adherence to standards and enhance safety standards and operational performance in foundries.